Rohan Shah

My name is Rohan Shah, and I am excited to work at the intersection of robotics, energy, and aerospace. I am currently a Junior at the Olin College of Engineering Studying Electrical Engineering. Ever since I was a kid, I have been inspired by science fiction and NASA to dream of the stars. I believe that the future is bright, but can only be realized by building it. I also love to sail and dream of sailing the Mediterranean. I have recently started hiking and have spent a summer hiking in the Whites of New Hampshire and the Cascades/Olympics near Seattle. My favorite peak was Mt. St Helen's. Looking down into the crater was a strange and awe inspiring site.

Projects

Outside of my academic work, I have pursued on several passion projects to create things that I believe should exist. These projects have allowed me to develop skills both in and out of my discipline.

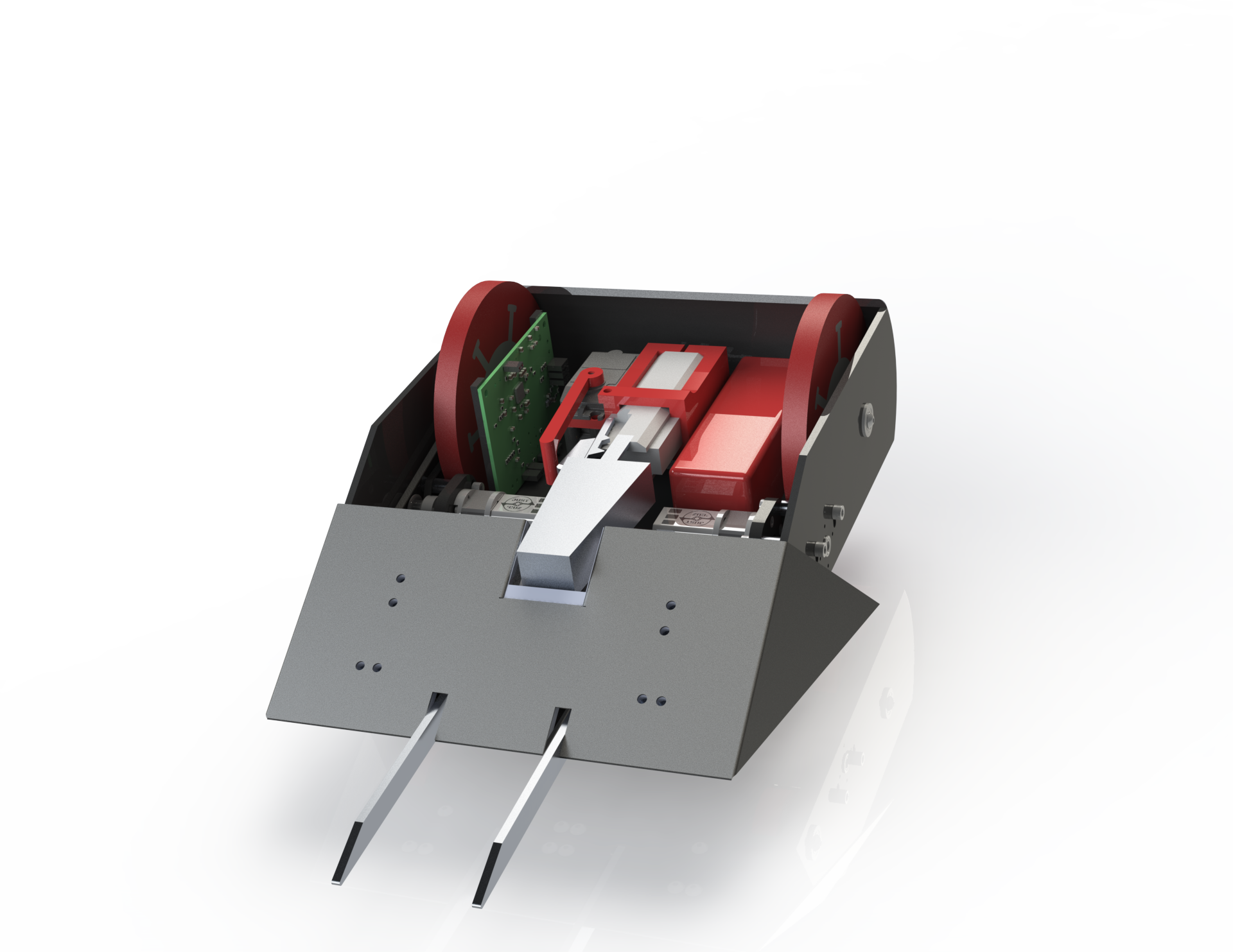

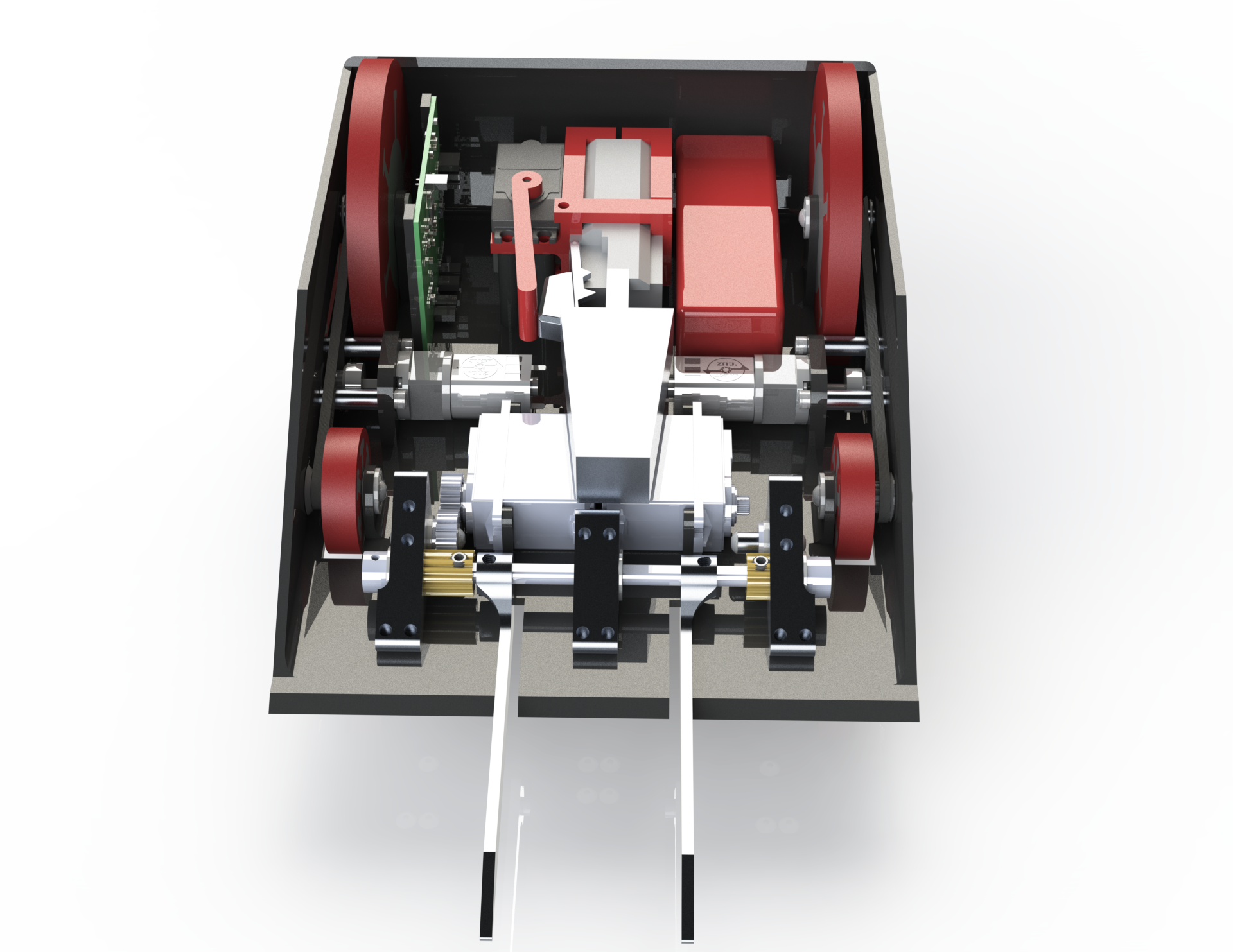

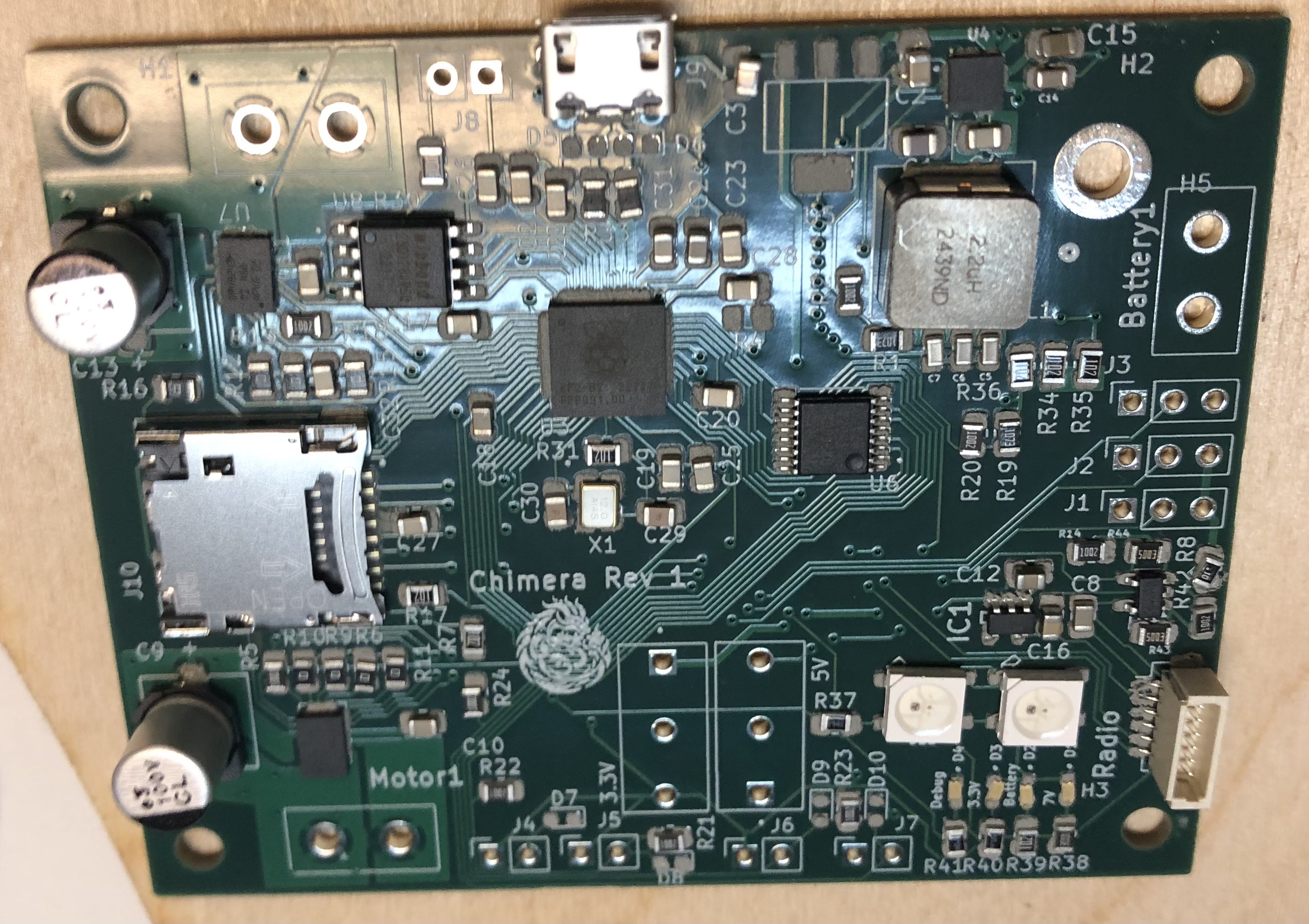

Chimera

I am currently working on a small beetleweight combat robot. I have been designing the robot in my spare time and hope to compete at NHRL late this year. Chimera is a lifting-flamer robot that I am designing with fully custom electronics. I am desinging off-meta because my primary interest is to build for fun, not to build a particularly competitive robot. The PCB and electronics were designed in Ki-Cad. I am currently bringing up the second revision of the boards. I have started manufacturing the mechanical components of the robot, with wheels, axles, and other systems being produced.

Olin Rocketry

My freshmen and sophomore year I was a member of my colleges rocketry team. I worked on developing our flight avionics hardware as well as writing firmware in C++. I worked on developing a Kalman filter that would allow us to control adjustable drag surfaces. Below is a picture of the finished avionics

Professional Experience

Stoke Space Avionics Intern – Summer 2025

At Stoke, I was tasked with designing a HIL Simulator of an Electronic Safe and Arm Device for FTS to verify our FTS system on the ground, and to pave the way for a flight in-house ESAD. The ESAD is responsible for arming, safing, and triggering the Bulk Destruct Charge, which is responsible for terminating thrust in the rocket in the case of an anomaly to safeguard the public. This requires a high voltage, high current pulse (1000V 1000A) to be delivered with a rise time of less than 100ns. This was the core challenge of the project, requiring careful part selection and layout to create a low inductance firing path, while standing off low-voltage electronics. The board also contained discrete logic to trigger the firing, safeing, and arming circuit. These logic systems were built with simple logic gates to reduce power consumption and remove firmware. The project required that I get up to speed with FAA/Range requirements in the form of RCC-1,9 along with the accompanying tailoring documents. By the end of the internship, I had successfully brought up a Rev 0 board spin, verifying the digital logic systems and successfully creating the high voltage pulse.

TTM Advanced Manufacturing Group – Summer 2024

The summer after my freshman year, I worked at TTM's Advanced Manufacturing Group where I worked on characterizing additive PCB manufacturing methods for run to run consistency and worked on updating a top and bottom layer inspection machine. The group was responsible for designing automated tooling for PCB production, focusing on pre-layup punching machines. I learned about how PCB's are produced with a focus on inner layer processes and photolithography. I also tried my hand at drafting, converting old paper drawings of designs into 3D digital designs.

Academics

I am currently in my Junior Year at Olin College majoring in Electrical and Computer Engineering. This semester I am taking Electromagnetic Theory at Brandeis, Probabilistic Design Optimization, and Many of my classes are project based and so below are some of the projects that I made for those classes. Outside of my technical course work, I am pursuing an humanities concentration in Philosophy by cross registering at Wellesley College.

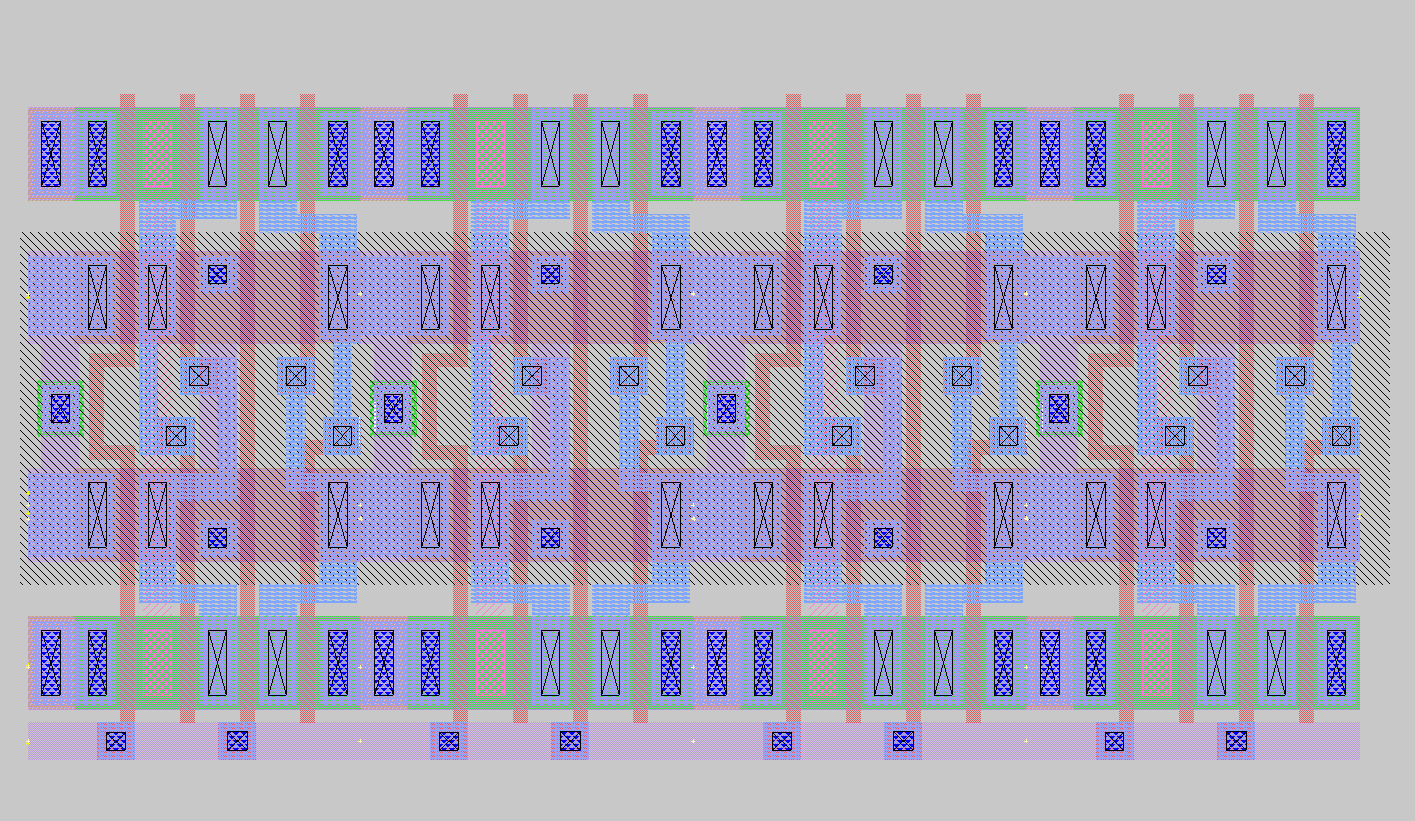

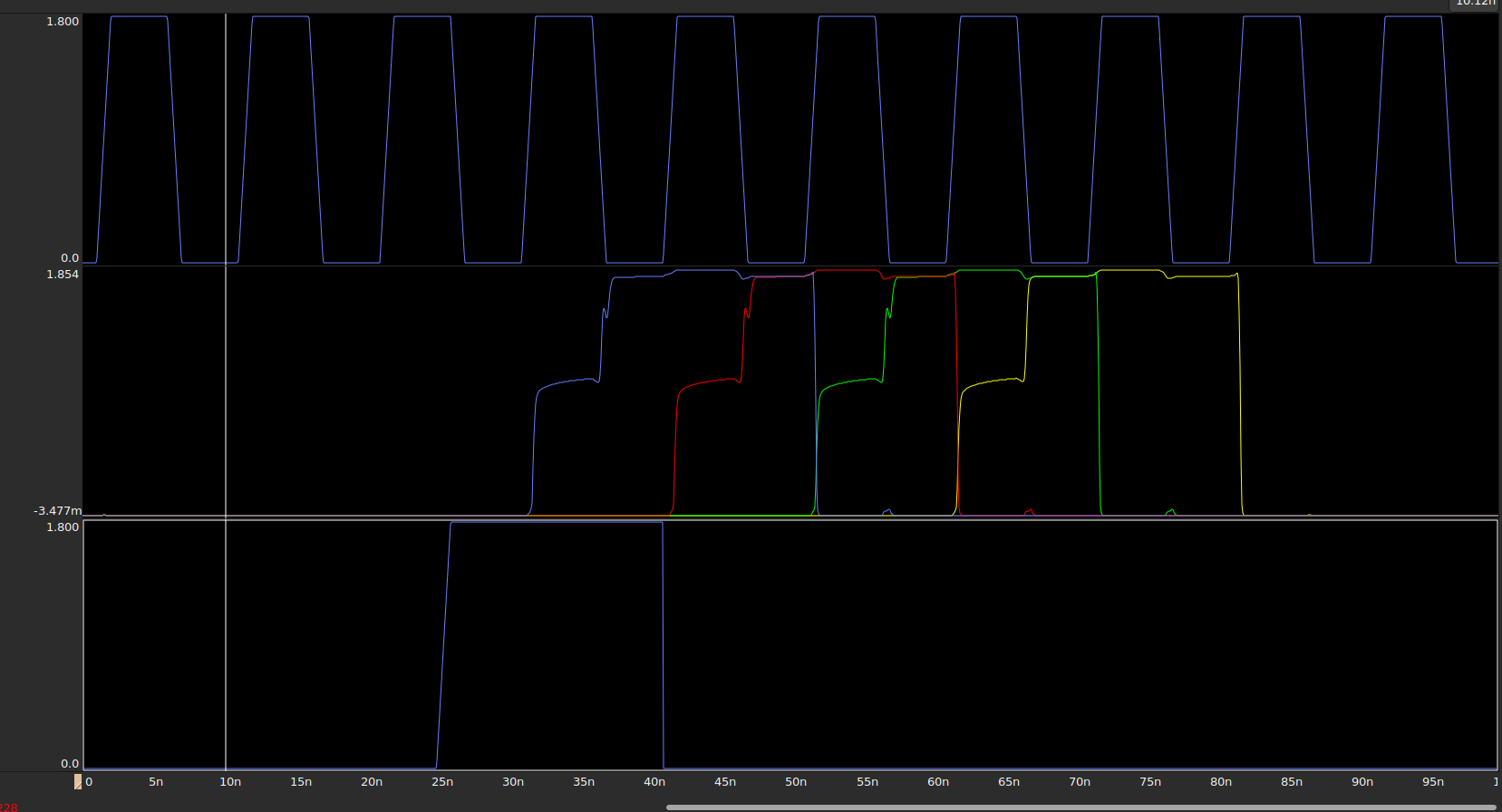

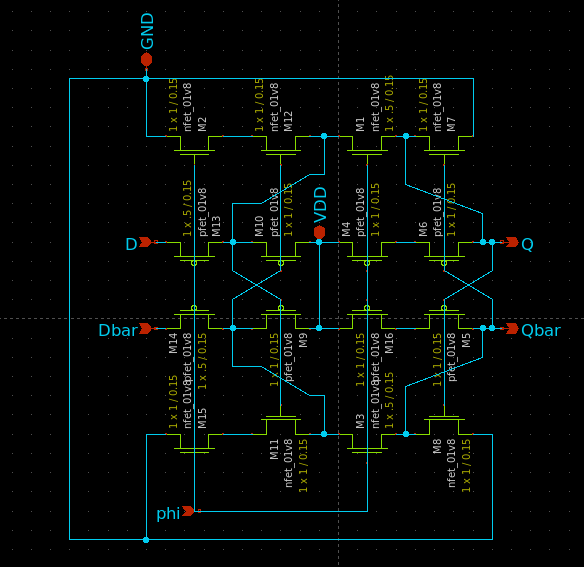

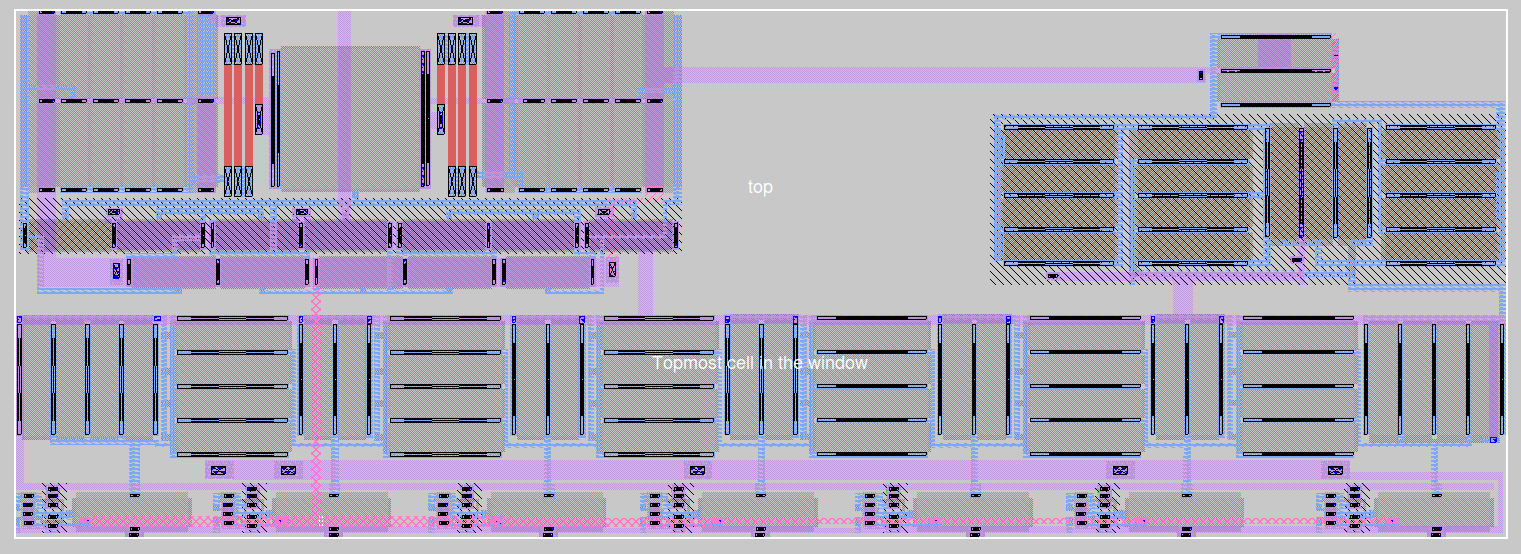

Mixed Analog Digital VLSI

This fall I took Mixed Analog Digital VLSI with Professor Brad Minch. The class used the Skywater 130 PDK and covered the basics of Digital, Analog, and Mixed Signal

IC development. The class covered digital logic design, amplifier design and analysis, and strategies for analyzing and developing novel analog circuits. We focused on low power design

using a 1.8V supply and developing circuits that self biase and can work without trimming internal components.

The class used an open source tool chain including XSCHEM and Magic for schematic and layout design. Throughout the class we completed a series of projects including designing

logic gates, an array-able flip flop, a ladder DAC, and for my final project a time based ADC. For my final project I was inspired by work done by Jung and Shin as well as Hang's PHD thesis on the subject.

Below are some layout and simulations from the various projects I worked on throughout the semester.

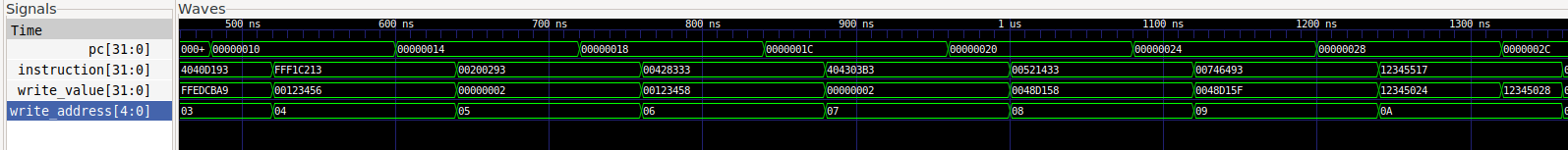

Computer Architecture

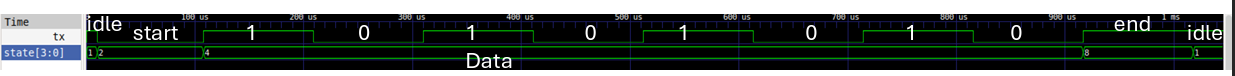

Computer Architecture walked from logic gates to designing a RISC-IV processor. During the class we used a ICE-0 FPGA Dev Board to complete a series of mini-projects covering the basics of implementing state machines, fetches from memory, and counters. For the final mini-project we were tasked with designing a RISC-IV processor. I designed a processor with a Harvard Architecture. Here is a picture of the block diagram I used to develop my processor. I developed automatic test benches in System Verilog to verify the function of the processor. For my final project I developed a memory mapped soft UART core for the processor and tested it in simulation. All of the development files can be found on my github.

Principles of Integrated Engineering: Thorondor

In the fall of my sophomore year I took PIE. My group and I built an RC tilt rotor bicopter inspired by a V22 Osprey in 6 weeks with a budget of 250 dollars. I was responsible for the avionics hardware and the control algorithms. I explored different control schemes and non linear iterative solvers to find the optimal combination of rotor direction and thrust. By the end of the course we were able to briefly sustain controlled flight before pitch instability ended the flight. This was due to the processor we used, an ARM-M0, only being able to sustain a 200Hz control loop. This resulted in pitch oscillations that we were unable to damp. We thoroughly documented our project on this page.